PCB Photosensitive Dry Film 30cmX1meter sheet

Description

PCB Photosensitive Dry Film sheet

Feature:

Width: 30cm

Longth: 1M

1.5 mil thickness of dry film can be completely cover a hole of 0.25 inches

The dry film can be used in the most ordinary plating solution, no wrinkle, no discoloration

It can cut into 10pcs 15cm x 20cm film,and 5pcs 20cm x 30cm film. You can cut it as you like

Operating steps:

The following are the steps, and the detailed tutorial will be released later, which is quite easy to succeed.

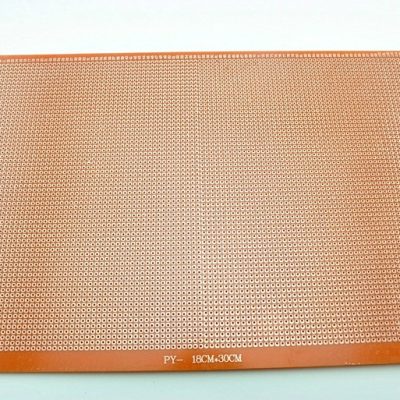

1. Polish the copper clad plate. This is simple, and it can be polished with the finest water sandpaper.

2, uncover the film, the photosensitive film is sandwiched between the two layers of film, first tear off one side can be torn by means of transparent adhesive tape, try a few more.

3, then film, a little copper plate can be cleaned, flat, try not to have bubbles.

4, after the film is used, the plastic machine is used, not too hot, fixed at about 100 degrees.

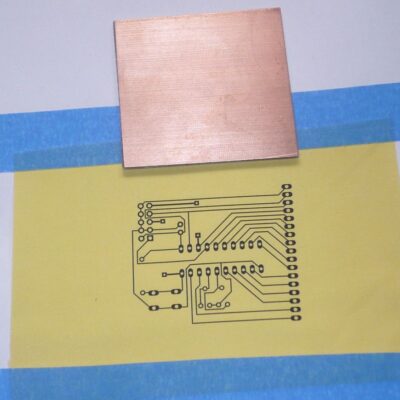

5, with inkjet film and laser film, you can achieve the highest fineness, if you do not require the use of sulfuric acid paper for printing accuracy. (The high precision is shown below )

6, the printed circuit diagram is placed on the photosensitive plate, (dry film is negative, so to reverse printing, we provide 99SE and AD printing tutorial) energy-saving lamp exposure for about 8 minutes, exposure machine for 1 minute, the sun 30 seconds -Approximately 60 seconds, the exposure process is obvious, because the photosensitive film will change color when exposed, from light to dark blue. You will easily see your circuit diagram appear on the board.

7. Development, tear off the protective film on the panel and put it into the developer (developer is 1:100, 10 g to 1 L of water). When developing, use a brush to wipe the board with a little force.

8, etching, environmental etchant water 1:4 fast, clean, no smell.

9. After the etched circuit board is stripped, remove the unnecessary film to expose the copper. The release agent is 1:50 water, soak it for a few minutes.

10, after the completion of the board, very good and very beautiful, the most dense line spacing is 0.1MM, line width 0.1MM, although it is easy to do 0.1MM line, but do 0.1 line and 0.1 line distance dry film It can also be easily made.

Additional information

| Weight | 0.005 kg |

|---|

1 review for PCB Photosensitive Dry Film 30cmX1meter sheet

You must be logged in to post a review.

TIP41

Smd Chip Capacitor size 0402 5.6pF

Relay Module 5V 4CH Active High Trigger

Refund Policy for UGE Electronics “Https://uge-one.com “

1. Returns and Refunds

Thank you for shopping at UGE Electronics “Https://uge-one.com “. If you are not entirely satisfied with your purchase, we’re here to help.

2. Eligibility for Refund

To be eligible for a refund, please make sure that:

– The item was purchased in the last 14 days.

– The item is in the original packaging.

– The item isn’t used or damaged.

3. How to Initiate a Refund

To initiate a refund, please contact our customer support at [[email protected]] or [01066552125]. Provide your order number and details about the product you would like to return.

4. Refund Processing Time

Once we receive your item, we will inspect it and notify you that we have received your returned item. We will immediately notify you on the status of your refund after inspecting the item.

If your return is approved, we will initiate a refund to your credit card (or original method of payment). You will receive the credit within a certain amount of days, depending on your card issuer’s policies.

5. Shipping Costs

Shipping costs are non-refundable. If you receive a refund, the cost of return shipping will be deducted from your refund.

6. Exchanges

If you wish to exchange an item, please contact our customer support. You will be responsible for the return shipping costs, and we will cover the shipping costs of the replacement item.

7. Damaged or Defective Items

If you received a damaged or defective product, please contact us immediately for assistance. We will work with you to resolve the issue promptly.

8. Contact Information

If you have any questions about our Refund Policy, please contact us at [[email protected]].

Important Note: This Return & Refund Policy is applied only for Orders invoiced VIA UGE Electronics, and regarding any Orders has been invoiced VIA any Other Vendor you can check the Return & Refund Policy of this Vendor VIA the Vendor Stroe Page, and it’s not our responsibility for any issue between you and the Vendor.

Ramadan Morsy (verified owner) –

Excellent product, recommended for student and amatures.